Curtis Kline

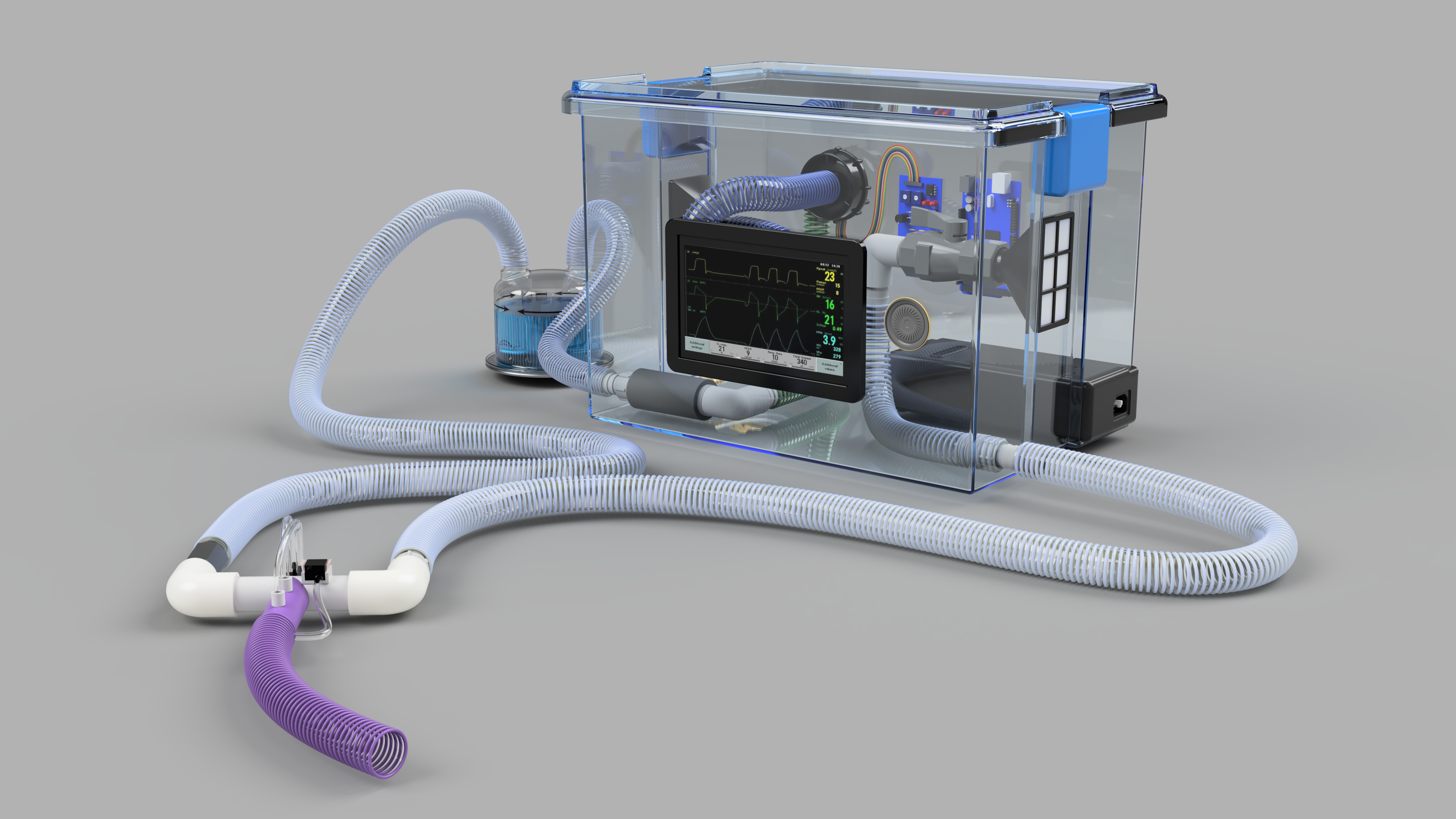

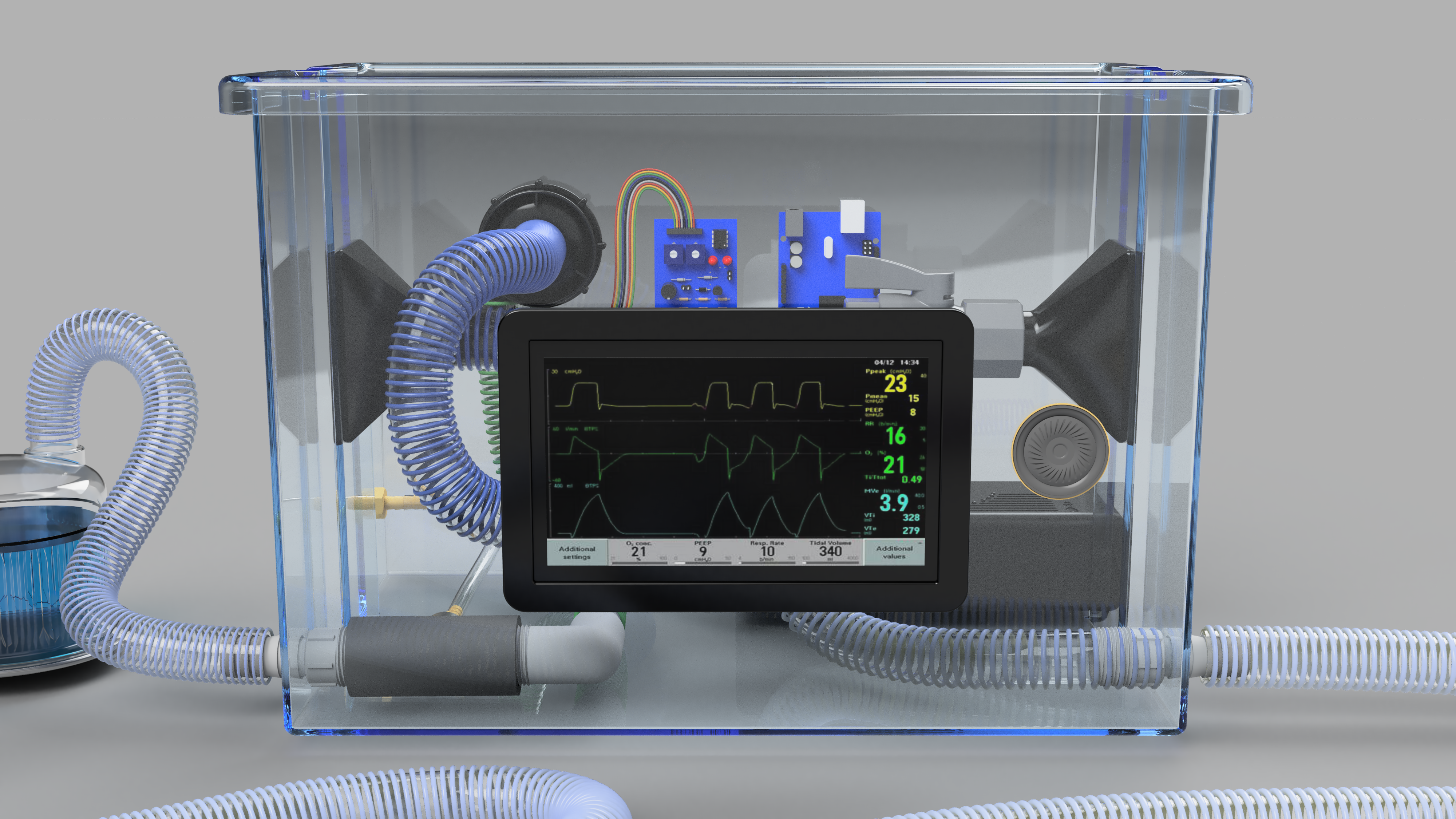

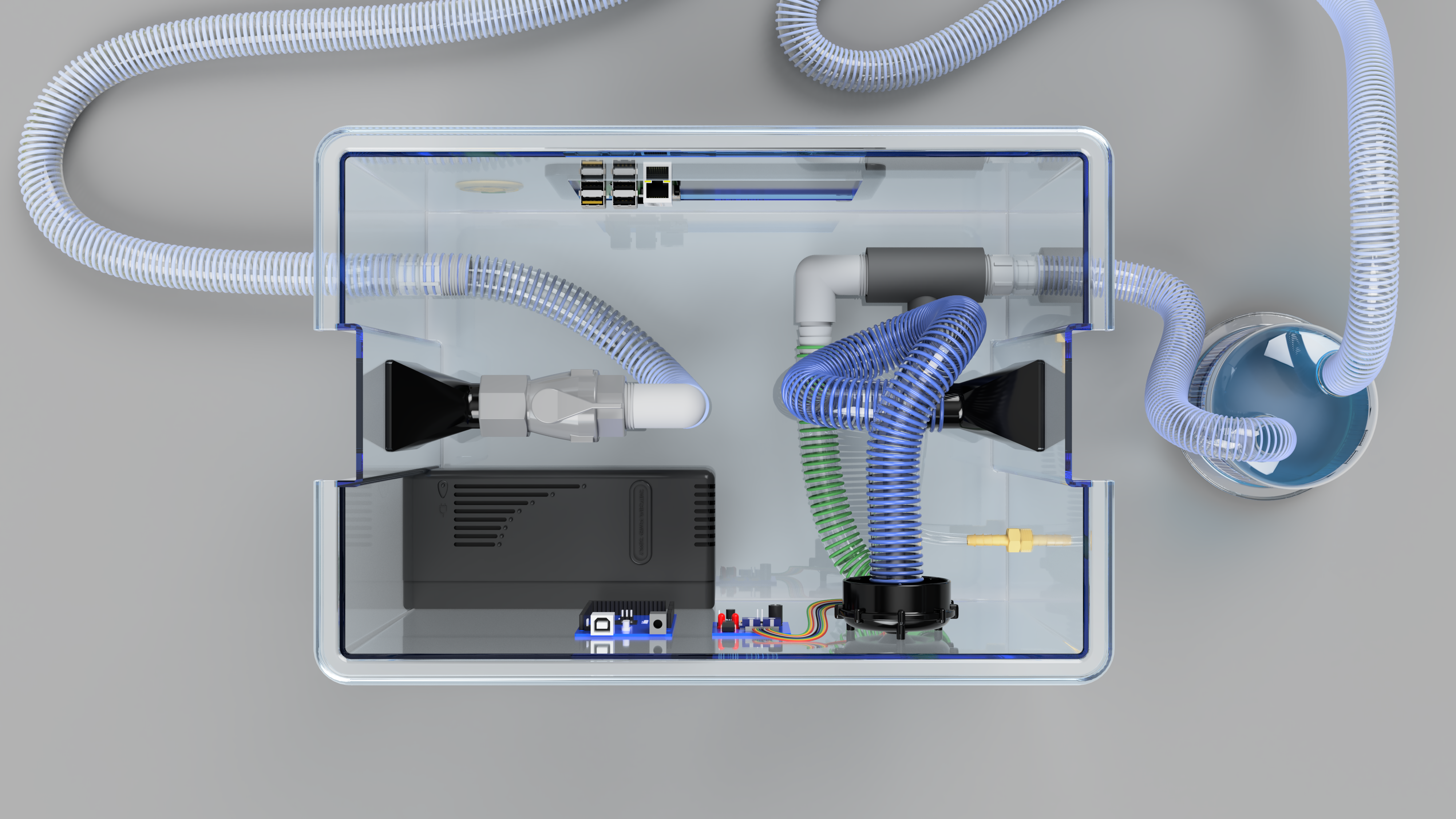

There are not enough ventilators for COVID-19 patients in any country, let alone in developing countries that lack the capital resources of the developed world. These countries too often depend on used medical equipment from wealthier nations, or must purchase expensive devices from the very same supply chains that the US and Europe rely on. While there is a proliferation of simple ventilator designs, treating COVID-19 patients requires relatively sophisticated ventilation, with both pressure and tidal monitoring in addition to PEEP. Our design centers around a low inertia centrifugal blower, currently sourced from CPAP machines. These brushless fans with lifetime lubricated bearings can spin to high speeds very quickly, allowing a fine degree of time-resolved pressure control. At the same time, they can develop pressures well above 40 cmH2O; even accounting for flow losses, our test model exceeds 100 cmH2O. By monitoring patient airway pressure using high-frequency pressure transducers and measuring patient tidal volume using an orifice flow sensor, we can reproduce any flow/pressure signal required. While our current design uses commercial NXP sensors, we are testing whether three BME280 sensors would provide sufficient resolution and redundancy at reduced cost. The other essential component of our design is the algorithmic controls. The software design must be able to detect inspiratory effort while maintaining PEEP, and it must control fan speed to hit a constant flow rate with variable compliance lungs. By using software-in-the-loop development?we have a simulated model of a lung and ventilator in Modelica?and a large team of software engineers around the world, we can rapidly accelerate algorithm development. What you end up with is a physically simple, low cost system totaling less than $300 USD that can be produced at scale.